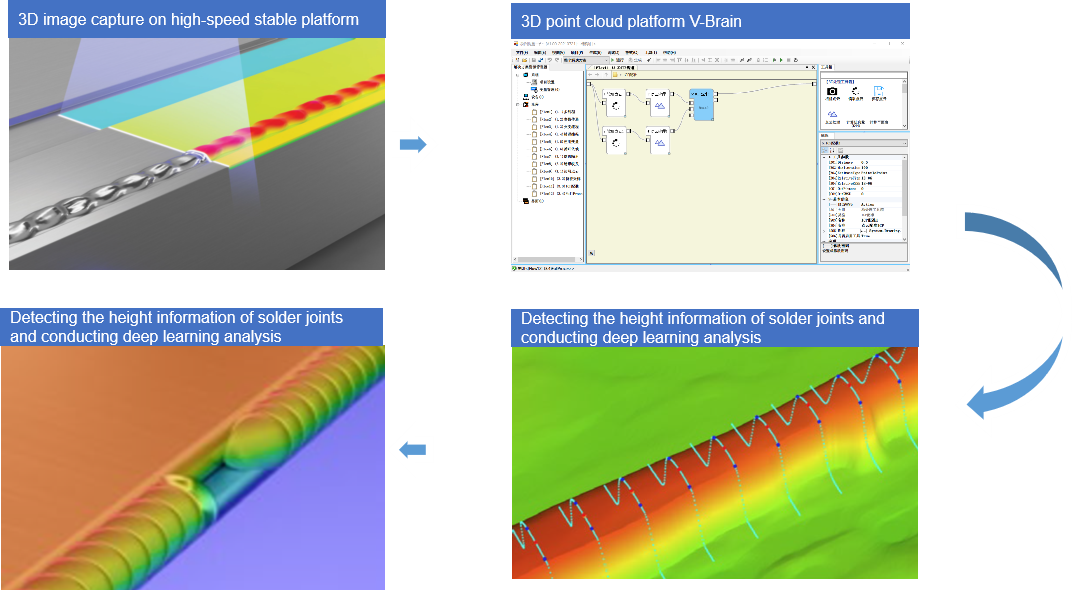

1. Core technology

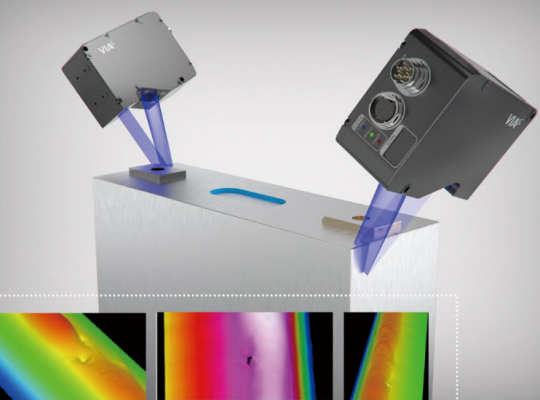

Customized imaging technology 3D camera angles to capture the welding area of battery cells

Compatible with multiple sizes of products, no need to replace components

Targeting the development of stable 3D algorithms

Defect detection rate>99%

Classification accuracy>95%

Online high-speed detection

T/T 5s/pcs (800mm x 320mm x 160mm)

Classify welding defects based on customer needs

Whether to manually repair welding based on defect classification to reduce welding defects

2. Application industry

Welding of new energy lithium battery top cover: detecting welding defects on the long and short sides of the top cover welding

This field is at the forefront of technology

3. Benefit manifestation

Accurately detect welding defects and eliminate the need for visual inspection personnel

Automatically pick out welding defects that can be repaired, increasing production line output